Quality Management

- GINTOU

Plastic printing packaging is a comprehensive and meticulous process for quality management, involving multiple aspects such as raw material screening, production process monitoring, and final product inspection.

1. Standardized operating procedures: Develop detailed operating instructions to ensure that each production process has clear operating guidelines and quality standards, such as the standards specified in GB/T 36064-2018 “Quality Control and Inspection Methods for Plastic Flexible Packaging gravure Printing Process”.

2. Quality control of raw materials: Strict testing is conducted on raw materials, including physical and mechanical properties such as thickness and friction coefficient, to ensure compliance with production requirements.

3. Real time monitoring of the production process: Implement real-time monitoring during the production process to ensure that production conditions such as temperature, pressure, and speed meet process requirements, and promptly solve problems in the production process.

4. Product quality inspection: Conduct quality inspection on the produced flexible packaging products, including barrier performance, mechanical strength, sealing performance, etc., to ensure that the products meet the expected quality standards.

5. Employee training and responsibility system: Improve employees’ quality awareness through regular training, clarify the quality responsibilities of employees at all levels, and establish a quality and safety responsibility system.

6. Environment and site management: Ensure the cleanliness, safety, and orderliness of the production environment, and establish corresponding management systems, such as the clean, safe, and hygienic production system and the production workshop management system.

7. Emergency measures and risk management: Develop emergency measures to respond to potential emergencies and accidents, and reduce the impact on production and product quality.

8. Continuous improvement: Through customer feedback and internal audits, continuously improve the quality management process to enhance product quality and customer satisfaction.

9. Recording and Traceability: Maintain detailed production and quality records to ensure product traceability, such as quality records related to quality and safety management responsibilities.

10. Modernization of technology and equipment: By adopting modern production conditions and testing methods, combined with the material supply conditions of China’s printing industry, setting target values and tolerances for the production process and products, and ensuring the quality of printed products throughout the entire process from data files to final printed products.

Through these measures, plastic printing and packaging enterprises can establish a comprehensive Japanese style quality management system to ensure high standards and quality of products, meeting the needs of the market and customers.

There is an online real time inspection system for printing machines

Detect defects during processing and ensure safety.

|

|

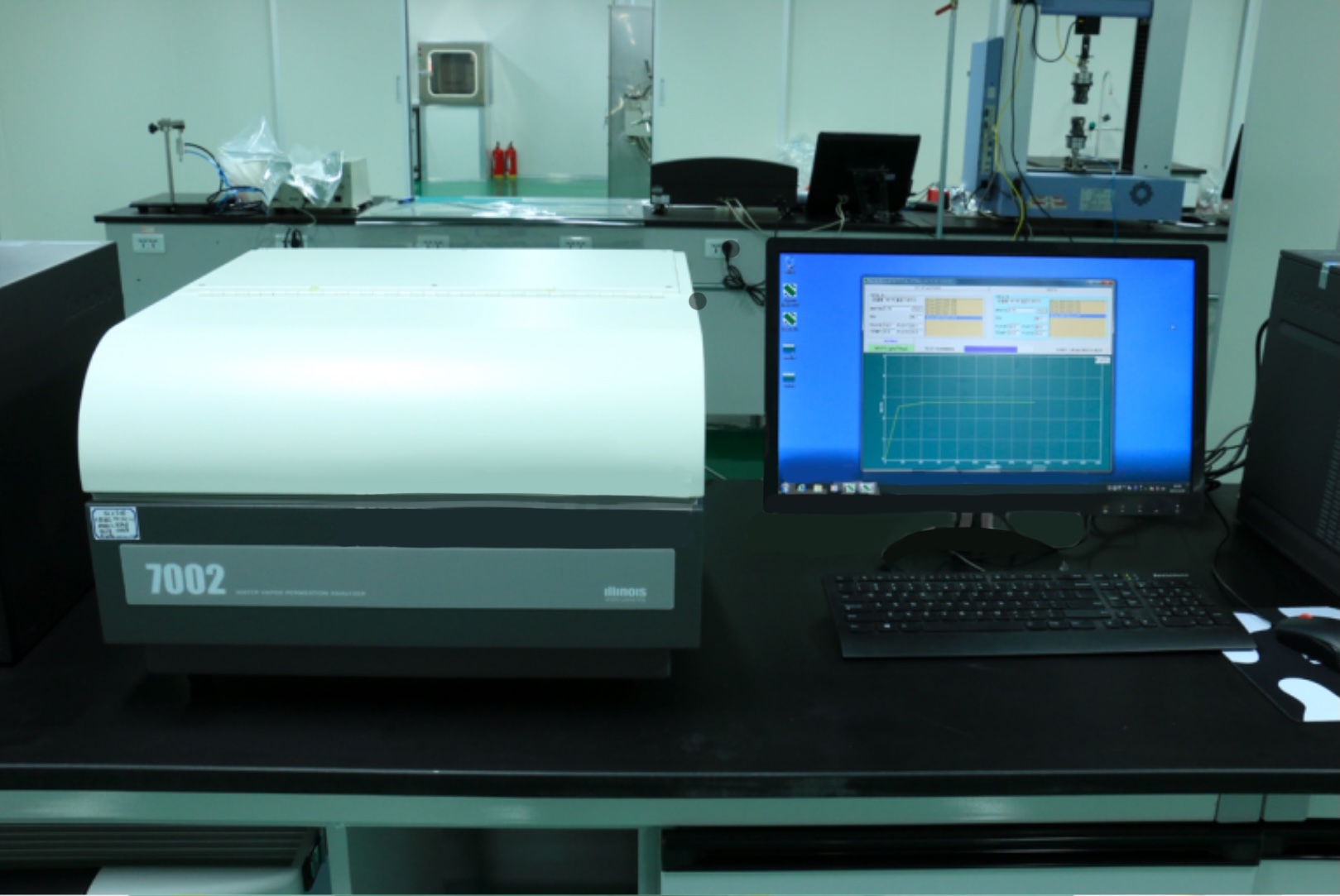

Laboratory test equipment

Our laboratory has professional inspection facilities to support accurate data for products.

|

|

|

|

|

|